3D Laser scanning services & As-Buit Surveys

We rebuild the geometry of elements and infrastructures using 3D laser scanner technology

Scan to BIM services

Scan to BIM is also popularly known as Point Cloud to BIM, because when buildings are examined with a 3D laser scanner, data is collected in the form of a point cloud (a group of millions of points in a 3D space). Experts import these point clouds into software tools such as Revit and convert them into 3D models ready for BIM. Scan to BIM services are used for As-built modeling and is one of the fastest growing platforms in the field of construction.

We produce complete and information-rich 3D BIM models from point cloud data. Our BIM Scan services are used due to our long-term experience of working on point cloud modeling projects.

Scan to BIM

Scan to BIM Service (As Built) is a way to capture a physical object's exact size and shape into the computer world as a digital 3-dimensional representation. It measures fine details and capture free-form shapes to quickly generate highly accurate data in a form of "point clouds" from the surface of an object.

We provide 3D Scan to BIM modeling services, using the latest technology to convert point cloud and laser survey data into complex 3D BIM models for leading architects, engineers, surveyors and contractors.

Our BIM models are usually created using Autodesk Revit (although we can also use other tools such as Graphisoft Archicad, Autocad ...). The scan captures are compiled from the rapid processing of millions of points (point clouds) and site images.

The laser scanner identify the surface details of a structure for the point cloud information. Therefore, point clouds include large precise amounts of data and can be converted to object-based BIM models, where the scanned data is converted to BIM data. Our point cloud modeling service at BIM creates precise models for construction purposes, as well as for remodeling and renovation projects.

Point cloud to BIM: We commonly combine models scanned to BIM for existing buildings with new / renovated area projects. Our models have beams, columns, ceilings, internal walls, external landscape elements and MEP accessories if necessary.

The production of 3D models or 2D models under previous construction conditions was carried out using manual survey methodologies. However, with the help of laser scanning the advantages of using scanning are forcing many companies to take the point cloud scan instead of manual capture.

In Scanphase we produce complete and information-rich 3D BIM models from point cloud data. Our BIM Scan services are used due to our long-term experience of working on point cloud modeling projects. We have a team of architects, engineers and modelers from Scan to BIM with experience in the work of complex renovation projects. We have worked on the renovation and restoration of heritage buildings, government buildings, old commercial properties, residential apartments that must be demolished or updated with newer designs. Scan to BIM modeling services are extremely useful for achieving excellent renovation results in less time and cost compared to traditional methods.

Remote laser capture for Scan to BIM

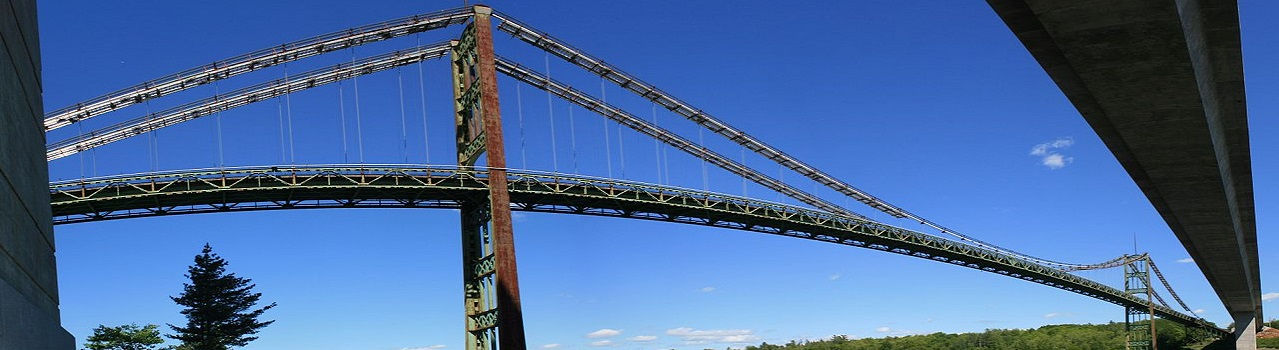

Large, complex structures with unique geometry and unique construction methods generally require a different approach to 3D laser scanning due to large open spaces. This approach is especially crucial to ensure that high-definition digital scans have precise adjustment and alignment.

Here is an example of one of our works that consisted in the capture by laser scanner of all the roofs from attached places reaching capture distances greater than 100 m. The main reason was the difficulty of access, the poor state of the same that represented a risk for direct measurement and the security elements that made the movements impractical. For each of the scanning locations, optimal locations were chosen to position the laser scanner to fully collect the necessary 3D data of the characteristics of that location for the 3D model. The scans took only a few hours. The scanned data was processed and refined, eliminating the strange data from the surroundings and focusing on the areas in question.

In conclusion, long-range laser scanning is a terrestrial technique for collecting large-scale, high-density 3D geospatial data from complex environments, such as entire buildings, factories, rooms, landscapes, other large structures and locations, both inside and out.

Scan To BIM: Planning 3D laser scanning projects

3D laser scanning is transforming the industry in terms of design, construction and visualization. Applications that support laser scanning, such as Scan-to-BIM, require that the data in the point cloud be of sufficient quality in terms of accuracy or density of points. Eliminating human error in a project is key to delivering quality results, reducing waiting times and minimizing costly mistakes.

Planning allows you to define the optimal set of scan locations while satisfying the specific quality and accuracy requirements of the job. Dedicating time to planning guarantees updated data and that the building / area coordinates are calculated and loaded correctly.

The planning must respond to four requirements:

-

The number of scans to perform.

-

If color scan data is required.

-

The difficulty of doing those scans. For example, scans on the site with limited access or scans with restrictions and traffic.

-

Idiosyncrasies of the site location.

In planning it is vital that the data is acquired in the most efficient way with the minimum number of possible scans. Here are some guidelines for doing it efficiently:

Step 1: Prepare for planning

Job planning and a control grid is critical to any project when it comes to laser scanning / 3D modeling. Sufficient time needs to be ensured in the pre-investigation stage of the project site for the right people to set up planning and generate a baseline control grid.

At this stage, it is determined how the information will be captured and it is identified where the stations and objectives should be placed on the site. You can record scan locations as you move through the area, make a hand-drawn sketch, or even a 2D floor plan for greater precision in plotting your scan points.

You should also ensure that the personnel assigned to plan the site are experienced in using the equipment you have chosen. For example, creating site inspection checkpoints may require different skills and equipment than 3D laser scanning.

Step 2: Plan the scan path and minimize the number of scans

Laser scanners perform measurements within the line of sight. Therefore, an environment with many pillars, small corridors, and other difficult-to-cover obstacles will require many more scans to cover than a larger but empty one. You should also consider things like the amount of detail required and what you want to do with the scans. There is nothing better than visiting the site, but if not possible a set of 2D plans and photos can help.

For small projects a visual inspection may suffice. For large and complex projects using modeling software can help by identifying theoretical scan locations to see where they overlap.

If the objective-based recording method is used, consideration should be given to where to place them. If a lensless registration method is used, you must ensure that there is sufficient overlap between the scans to obtain precise alignment. Depending on the software you are using and the uniformity of the environment you are scanning, an overlap of 30% to 50% will be required to precisely join the scans.

The goal of planning an exploration route is to ensure full coverage of the area, but also to try to minimize the number of scans to be performed. Basically if you can do fewer scans to get full coverage the whole process will be more efficient. Reducing the number of scans required not only reduces the amount of time on the site, but speeds up the registration process.

Step 3: Minimize errors

The combination of multiple 3D laser scans introduces errors, called propagation errors, and they are inherent limitations of the scanner that combine as the scans are combined.

For a composite point cloud, scans are built one after the other from an 'initial' scan. The more "steps" between any given scan and your "initial" scan, the greater the propagation error you will experience. They can be minimized, but can never be removed.

A critical step in site planning is deciding whether the total number of scans you will need to perform to obtain full coverage of the area will create more propagation errors than the precision parameters of the job specifications can handle.

The uncertainty increases according to the following equation: (n1 * 2) 2 + (n2 * 2) 2 ... = Total error, where 'n' is the error rate for each scan.

Therefore, if you have a scan error of +/- 1mm, it will increase to +/- 4mm for each additional scan that moves away from the "initial" scan. If that error spread number exceeds the parameters for the project, you will need to build a site grid, also known as a set of "survey control points" or "control network".

A site grid is a set of fixed targets throughout the area, each with a precisely measured known relative location.

By completing your site plan and capturing checkpoints, you can match the checkpoints to the point cloud during the registration process. If necessary, this is a critical step in the process of creating an accurate point cloud, regardless of whether you will be using targets to record 3D laser scans.

Properly assessing the number of scans required can eliminate the need to create a site grid, however, you will need to ensure that you get the precision you need for the project.

Step 4: Speed up the process

One of the biggest savings in using the latest generation of laser scanners and registration software is time. In the field, targetless scanning saves time by avoiding target placement and allows you to scan larger projects faster. But you may lose that time advantage later in the workflow if you have poor cloud-to-cloud alignment or need excessive scan overlap to ensure good registration.

During processing, you can create multiple 'zone' scans, building 'scan trees' as large as the accuracy requirements of the job needs, and further reducing propagation errors.

This will provide the ability to reduce the size of the data sets and then process them efficiently. It is especially worth looking for software that can take advantage of multi-threaded, cloud-based concurrent processing throughout the entire processing process, achieving increased processing speed.

Conclusions of good planning

3D laser scanning is reliable for its precision, reliability, speed, and ease of use. The adaptability and exceptional flexibility of 3D scanning make it ideal for measuring a wide range of elements in various locations. That confidence must be maintained by ensuring good planning and preparation.

Good business sense means that site visits and device usage should be kept to a minimum. By creating accurate site plans and associated control points, any costs in site planning are more than recovered by facilitating goalless scanning, optimizing high-quality point cloud recording and processing.